Our Solution

Detect and identify machine faults

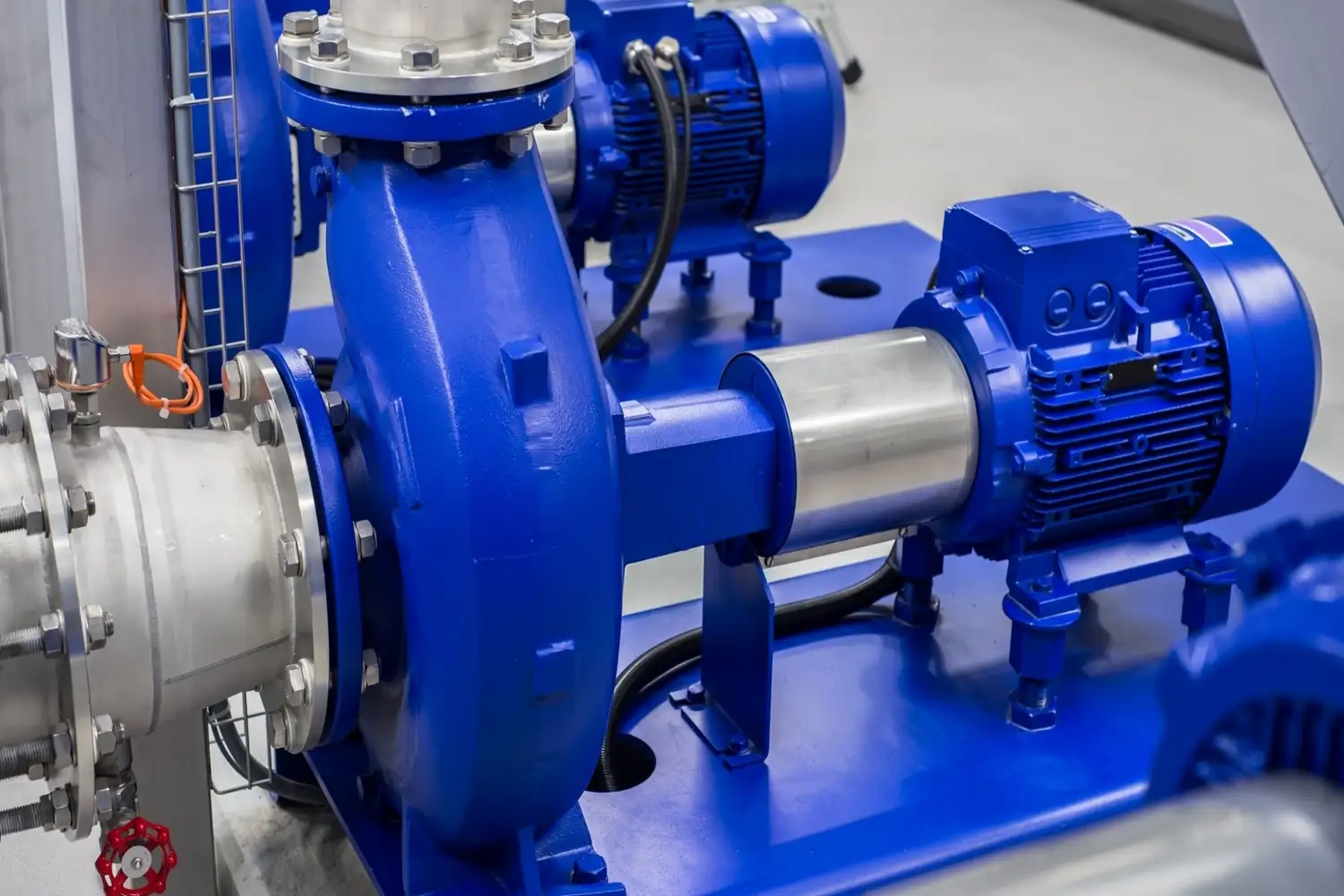

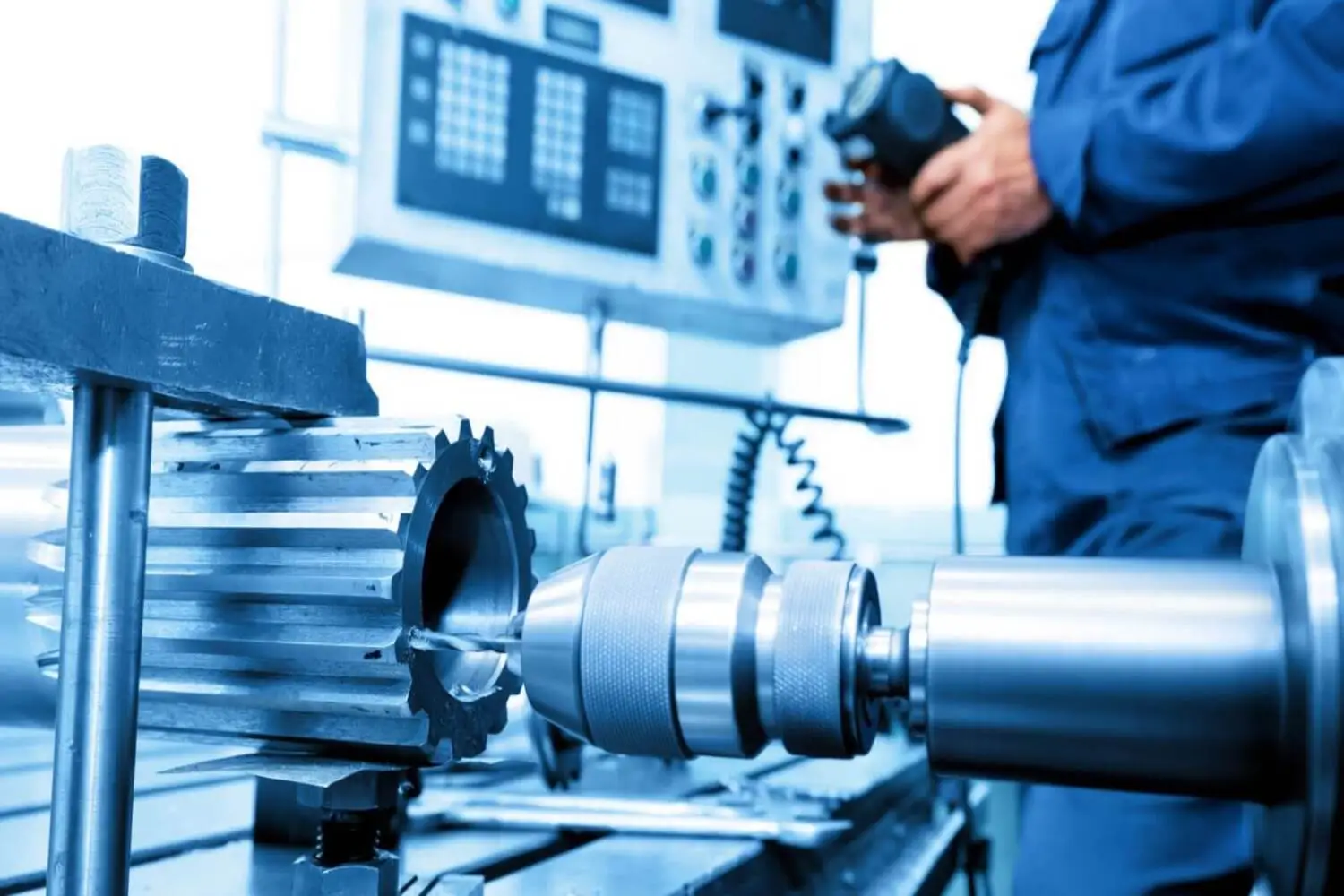

Diagnosis is the process of detecting and identifying faults in machines. The machine faults occur in the bearings, gears and shafts of a rotating machine, which if left unnoticed can cause heavy financial losses and severe accidents. Other types of faults that accelerate the machine degradation are misalignment and unbalance. In i-MoniTech, we use sensors to gather vibration, acoustic emission and temperature data to acquire the information related to machine health condition in a real-time manner. Our solutions deploy advanced signal processing techniques to extract fault features sensitive to premature faults. These features are used to train data-driven AI algorithms for developing robust health indicators and enhance diagnosis accuracy. Our solutions promise to improve machine productivity, reduce downtime, eradicate unnecessary maintenance actions, and minimize human intervention.

Are you facing these challenges?

Unplanned Downtime

Frequent and unexpected machine failures disrupting your operations and leading to costly downtime?

Production Losses

Financial losses due to unexpected halt in production lines, missed production targets, delay in fulfilling customer orders?

High Maintenance Costs

Spending excessive resources on unnecessary maintenance actions without addressing the root cause of machine issues?

Risk of Severe Accidents

Concerned about the safety hazards posed by unnoticed faults in critical components like bearings and gears?

Inefficient Operations

Struggling with reduced machine efficiency and productivity due to undetected faults and inefficient maintenance processes?

Key Features

Advanced Signal Processing

Utilize state-of-the-art signal processing techniques to accurately detect and identify machine faults in their early stages.

AI-Powered Algorithms

Employ cutting-edge AI algorithms for precise fault diagnosis, enhancing the accuracy and reliability of our solutions.

Real-Time Monitoring

Continuous, real-time monitoring of machinery to promptly identify issues and prevent unexpected breakdowns.

Predictive Maintenance

Shift from reactive to predictive maintenance, allowing for timely interventions and reducing unnecessary maintenance activities.

Comprehensive Reporting

Receive detailed diagnostic reports that provide insights into machine health, fault causes, and recommended corrective actions.

User-Friendly Interface

Benefit from an intuitive and user-friendly interface that simplifies monitoring and diagnostics, making it accessible for all levels of technical expertise.

The way we conduct our activities

1. Book service / onsite visit/ remote services

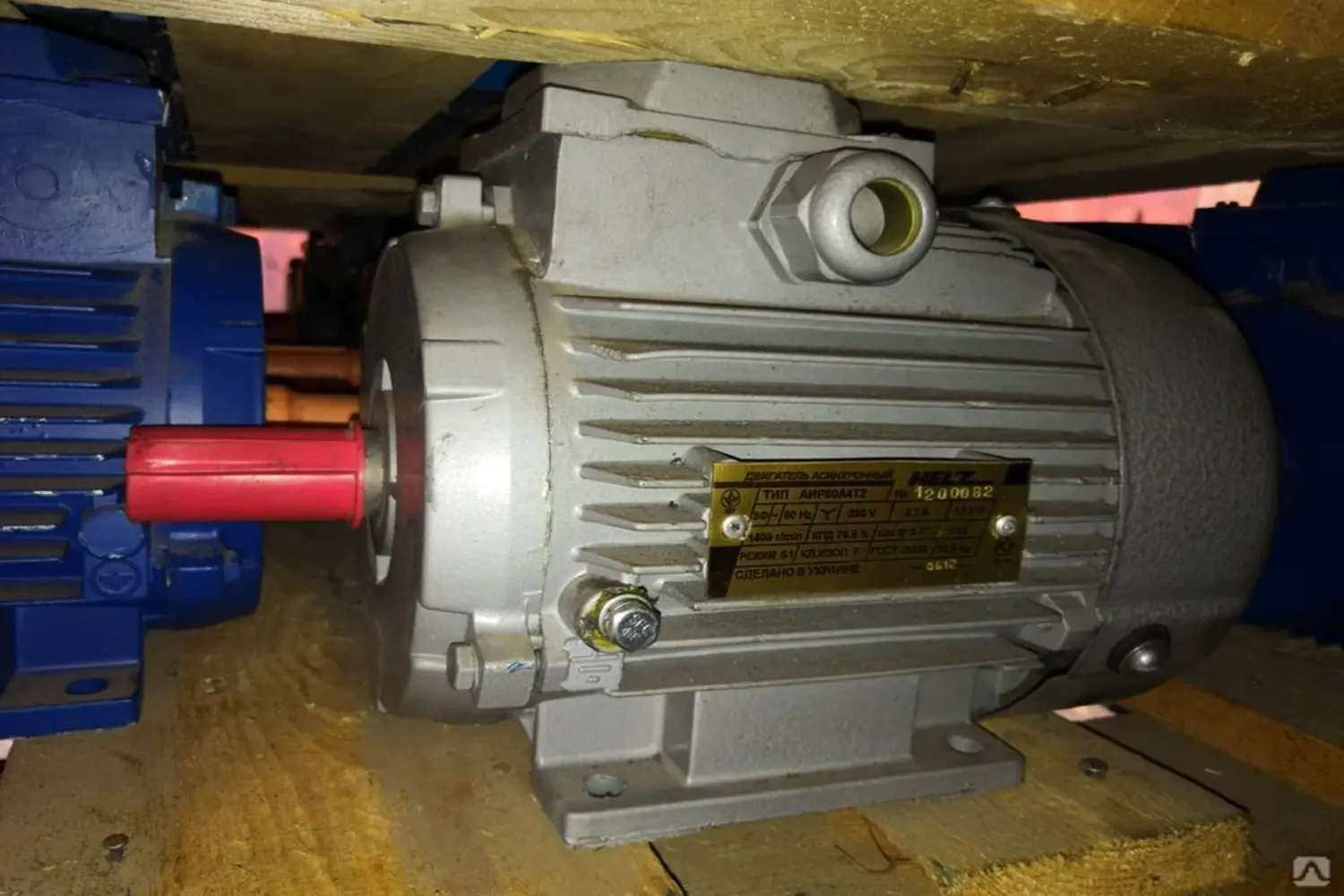

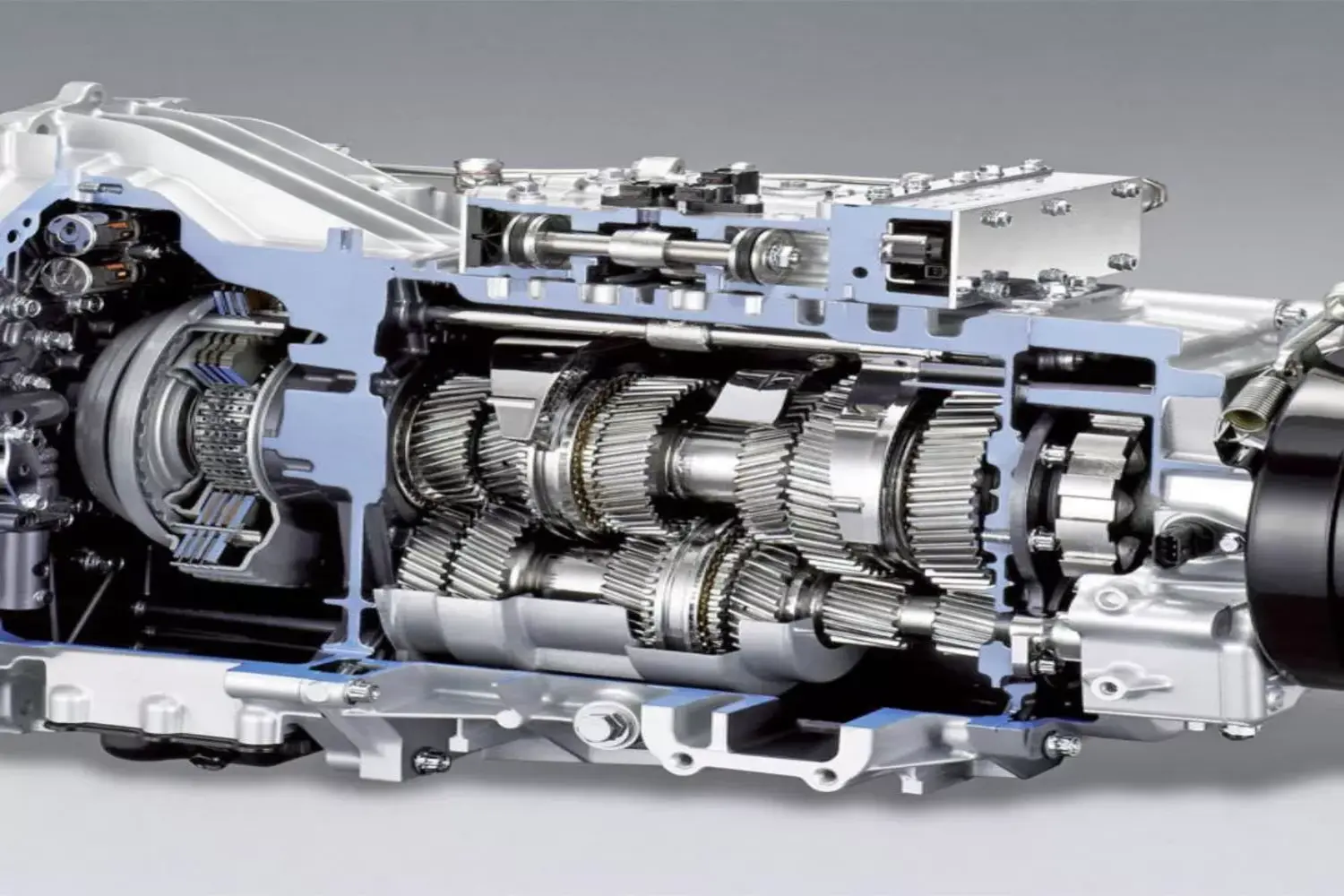

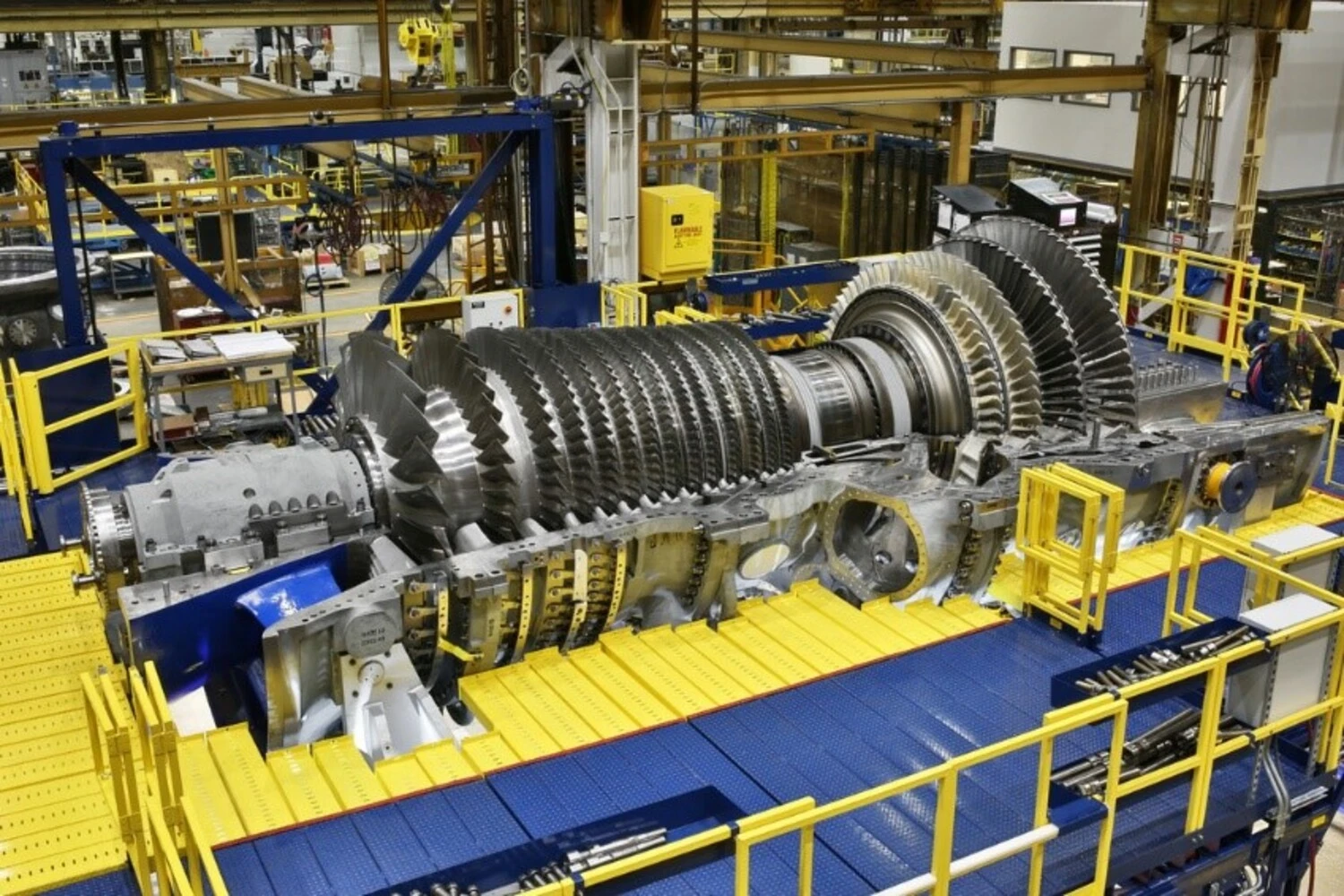

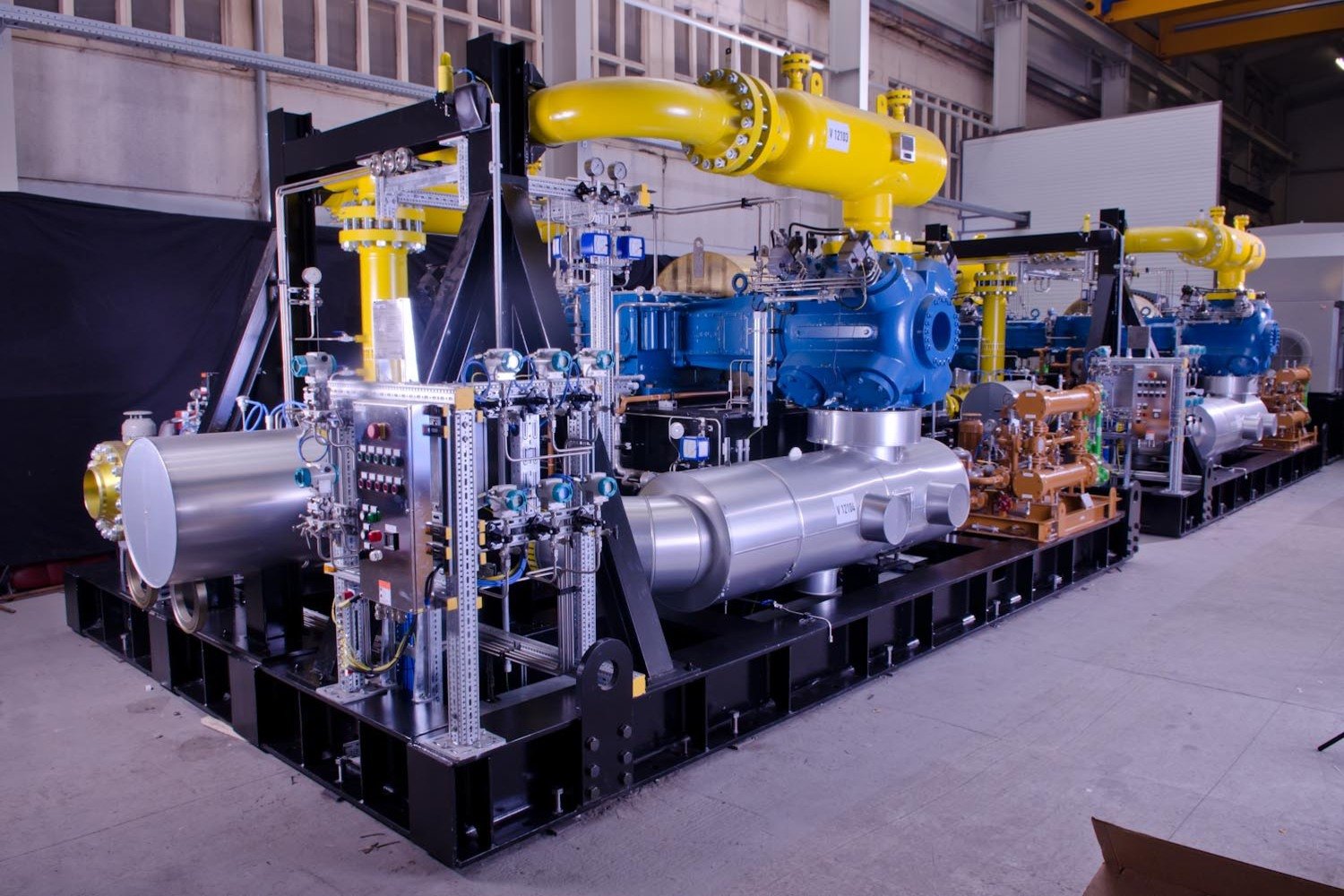

Client can book our services through phone call/email and our expert team visits the site to collect diagnosis data from critical machinery installed on the factory shop floor. Client can also share their machine data remotely if it is already available. Monitored machine include pumps, motors, gearboxes, turbines, compressors, engines and fans, etc.

2. Collect data via IOT sensors and devices

We install high-end IOT sensors and devices on the machine to collect vibration /acoustic emission/ temperature data to capture the machine health status. Data is stored and transferred to a PC for further analysis. We document the preliminary information about the machine operating conditions, past operation profile, process parameters fault symptoms, and other relevant technical details available with the client .

3. Signal processing and feature extraction

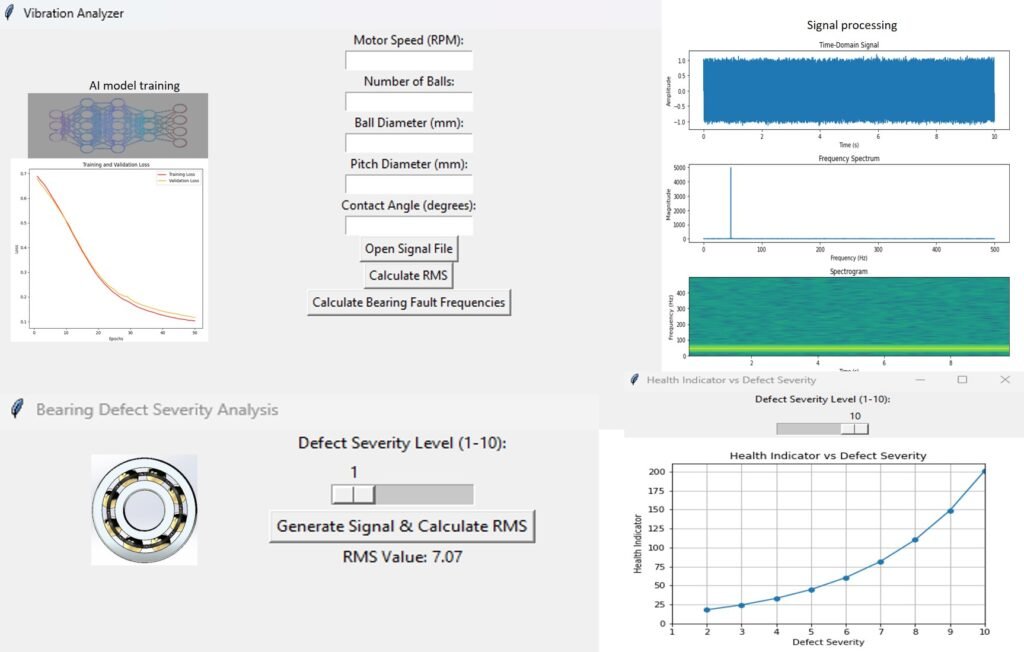

We offer innovative data analytics tools with a range of signal processing algorithms to discover superior fault features that can track the machine condition accurately and useful to build robust AI models. Features are extracted to reveal the time-domain, frequency-domain and time-frequency domain information embedded in signals.

4. Detecting faults through through AI

We use state of the art machine learning and deep learning algorithms to learn the fault patterns directly from the raw signals or through the fault features for identifying and classifying machine faults. Our solutions are designed to tackle challenges such as unavailability of failure data in training, missing data, imbalanced data and explainability

5. Visualization and Interpretation

Our software platform loaded with various data visualization and interpretation dashboards/icons enables the users to visualize the health indicators and forecast them in a real-time manner, set failure thresholds, get insights into analysis outcomes, and generate accurate failure alarms.

Machinery monitored

Pumps

Motors

Gearboxes

Turbines

Compressors

Engines

Fans

Faults diagnosed

Bearings

Gears

Shaft cracks

Belt and chain drive

Misalignment

Unbalance

Blade faults

What you get.

- Machine vibration and temperature records.

- Statistical features, RMS and kurtosis, trend.

- FFT spectrum records indicating fault frequencies.

- Advanced signal processing results indicating time-frequency information embedded in signals instantaneously.

- Health indicators generated by AI for tracking machine performance degradation.

- Fault types and their identification through AI.

- Detailed reports on probable cause of faults.

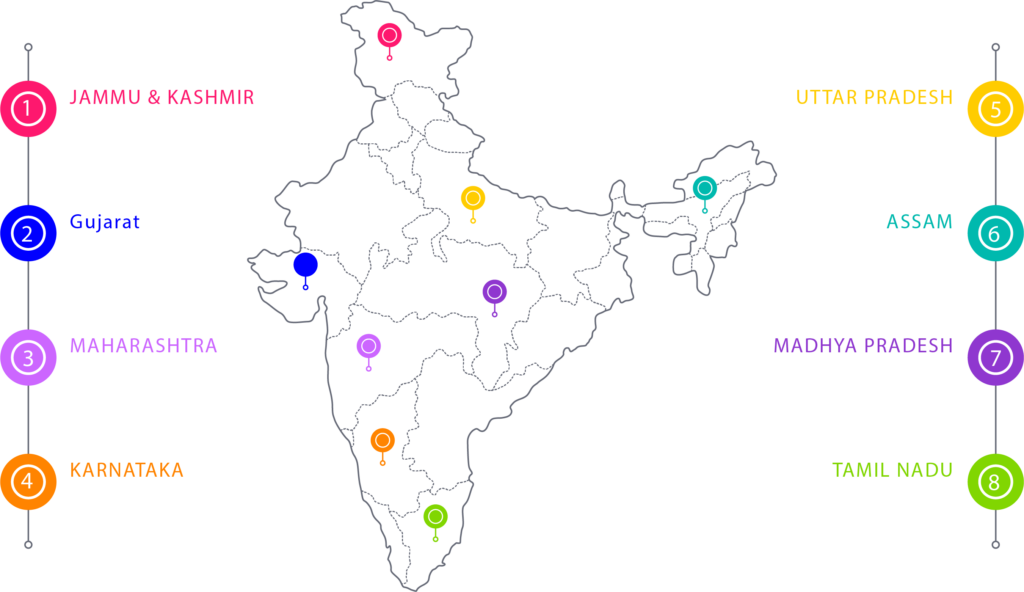

Regions We Serve